Breaking News

Iran (So Far Away) - Official Music Video

Iran (So Far Away) - Official Music Video

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Why America's Two-Party System Will Never Threaten the True Political Elites

Why America's Two-Party System Will Never Threaten the True Political Elites

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

Air-Breathing Aqueous Sulfur Flow Battery for breakthrough ultralow cost energy storage

•Chemical cost analyzed for 40 rechargeable couples developed over the past 60 years

•Aqueous sulfur/sodium/air system identified with ultralow chemical cost of ∼US$1/kWh

•Air-breathing flow battery architecture demonstrated at laboratory scale

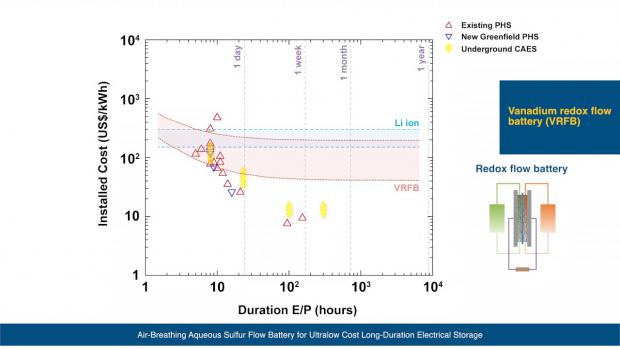

•Techno-economic analysis shows installed cost is comparable with PHS and CAES

Above – Curves for the present air-breathing aqueous sulfur flow battery approach using Na and Li chemistry are shown in green and gray, respectively. The chemical costs for Na and Li are shown as dashed lines. Curves of constant power cost show that the power stack dominates the system cost at short storage durations, whereas at long duration the cost asymptotically approaches the energy cost due to chemical constituents plus storage tank and related costs. 5 M concentrations of both Na and S are assumed, with cycling of the sulfur over the speciation range S22− to S42− corresponding to 25% of theoretical capacity.