Breaking News

Google is issuing a call to action:

Google is issuing a call to action:

Be first, be smarter, or cheat

Be first, be smarter, or cheat

The Next Plandemic: 3,625 Biolabs, Nipah Virus Patents, and Self-Amplifying mRNA Injections

The Next Plandemic: 3,625 Biolabs, Nipah Virus Patents, and Self-Amplifying mRNA Injections

HERE WE GO - SWISS FRANC HIT ANOTHER RECORD.

HERE WE GO - SWISS FRANC HIT ANOTHER RECORD.

Top Tech News

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

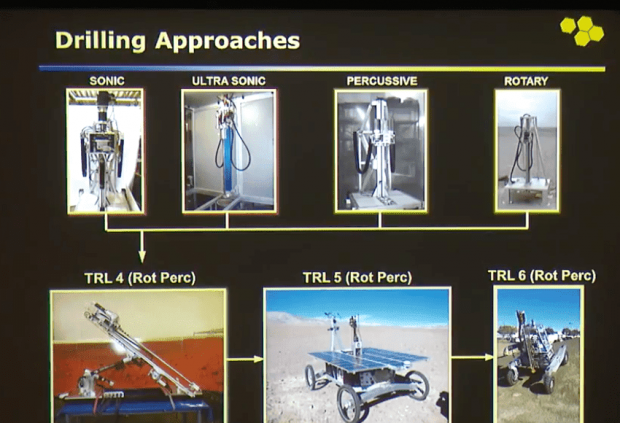

Drilling and mining on the moon

Project one is developing a sampling drill for volatile-rich lunar regolith as part of NASA's Lunar Resource Prospector.

There is technology development required to reach TRL 6, as well as the range of tests the system was subjected to. These tests include drilling in volatile-rich lunar analog soil and sample delivery inside a lunar chamber.

Project two involves volatile extraction technology for large-scale mining operations. In a more conventional approach, feedstock is mined and transported to a processing plant. Here, an alternative design will be presented that combines the mining and extraction steps into one and eliminates the transport step. I will present several approaches, vacuum chamber test data, and lessons learned.