Breaking News

No One Does It Like Johnny Carson | Mark Malkoff #470 | The Way I Heard It

No One Does It Like Johnny Carson | Mark Malkoff #470 | The Way I Heard It

Webb is ready - the open source tool that will decode the Epstein files for EVERYONE

Webb is ready - the open source tool that will decode the Epstein files for EVERYONE

Trump administration ending Minneapolis immigration Operation Metro Surge

Trump administration ending Minneapolis immigration Operation Metro Surge

TUMBLER RIDGE MASSACRE: The Trans Shooter Media TRIED TO HIDE...

TUMBLER RIDGE MASSACRE: The Trans Shooter Media TRIED TO HIDE...

Top Tech News

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

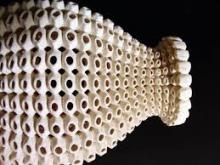

3D-Printed Ceramics Could Build Next-Gen Spaceships

Heat-shielding tiles on the space shuttle were made from ceramics, for example.

Now researchers have used a 3D printer to make customized ceramic parts that have also overcome the Achilles' heel of ceramic objects: their tendency to crack.

The finding could open the door to a new class of ceramic-body or ceramic-engine jets, perhaps even a hypersonic craft that can fly from New York to Tokyo in a few hours.

"If you go very fast, about 10 times speed of sound within the atmosphere, then any vehicle will heat up tremendously because of air friction," said Tobias Schaedler, senior scientist at HRL Laboratories in Malibu, Calif. "People want to build hypersonic vehicles and you need ceramics for the whole shell of the vehicle."

Schaedler and colleagues at HRL invented a resin formulation that can be 3-D printed into parts of virtually any shape and size.