Breaking News

2025-09-17 -- Ernest Hancock interviews James Corbett (Corbett Report) MP3&4

2025-09-17 -- Ernest Hancock interviews James Corbett (Corbett Report) MP3&4

Whistleblower EXPOSES How Israel Brainwashes American Christians!

Whistleblower EXPOSES How Israel Brainwashes American Christians!

Joe Rogan listens to "How to destroy America"

Joe Rogan listens to "How to destroy America"

Top Tech News

This "Printed" House Is Stronger Than You Think

This "Printed" House Is Stronger Than You Think

Top Developers Increasingly Warn That AI Coding Produces Flaws And Risks

Top Developers Increasingly Warn That AI Coding Produces Flaws And Risks

We finally integrated the tiny brains with computers and AI

We finally integrated the tiny brains with computers and AI

Stylish Prefab Home Can Be 'Dropped' into Flooded Areas or Anywhere Housing is Needed

Stylish Prefab Home Can Be 'Dropped' into Flooded Areas or Anywhere Housing is Needed

Energy Secretary Expects Fusion to Power the World in 8-15 Years

Energy Secretary Expects Fusion to Power the World in 8-15 Years

ORNL tackles control challenges of nuclear rocket engines

ORNL tackles control challenges of nuclear rocket engines

Tesla Megapack Keynote LIVE - TESLA is Making Transformers !!

Tesla Megapack Keynote LIVE - TESLA is Making Transformers !!

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Methylene chloride (CH2Cl?) and acetone (C?H?O) create a powerful paint remover...

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Engineer Builds His Own X-Ray After Hospital Charges Him $69K

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

Researchers create 2D nanomaterials with up to nine metals for extreme conditions

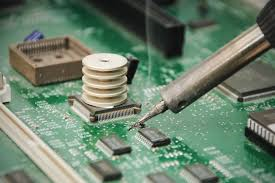

Liquid-metal particles enable heat-free soldering at room temperature

The new form of liquid/solid hybrid has practical applications in heat-free soldering and electronic circuit damage repair.

The discovery of this new metallic form was made when researchers looked for a way to prevent liquid metals from returning to their solid state, even at temperatures below the point at which they normally solidify. Known as "undercooling,", the technique has often been used to analyze the inner workings of metal structures and to look at alternative ways of processing metals. However, the greatest hurdle in this area is that it is difficult to create significant amounts of stable quantities of these undercooled metals.

Looking at this problem in a different way, the Iowa State team hit on the idea of shrouding minute droplets of liquid metal with a thin, uniform coating that held the liquid inside a sort of particle capsule, to form a balanced batch of particles containing undercooled liquid metal.

This Is The Truth

This Is The Truth