Breaking News

California in Chaos Today! Atmospheric River Triggers Severe Flooding in Wrightwood

California in Chaos Today! Atmospheric River Triggers Severe Flooding in Wrightwood

THIS Is The Fastest Way To Get Dementia...The 6 Science-Backed Brain Fixes!

THIS Is The Fastest Way To Get Dementia...The 6 Science-Backed Brain Fixes!

2026 Will be the Year of Your Greatest Dreams or Worst Fears

2026 Will be the Year of Your Greatest Dreams or Worst Fears

Joe Rogan Experience #2431 - Shane Gillis

Joe Rogan Experience #2431 - Shane Gillis

Top Tech News

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Engineers Create Diesel From Water And Carbon Dioxide That Has Zero-Carbon Footprint

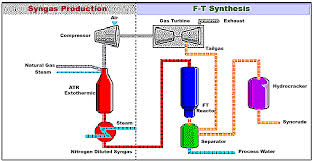

Utilizing the Fischer-Tropsch process, an underutilized technique which has been around since the 1920's, Audi engineers were able to produce a clean-burning diesel fuel. Not only is the fuel carbon neutral, it can be poured directly into current cars of today without modifying the machinery.

The German car manufacturer announced in 2015 that it had successfully created an "e-diesel," or diesel containing ethanol, by using renewable energy to produce a liquid fuel using nothing more than water and carbon dioxide. With fuel prices on the rise once again, the news has gone viral for understandable reasons.

It took just four months for a plant in Dresden operated by clean tech company Sunfire to produce results using the Fischer-Tropsch process. The fuel, named "blue crude," is composed of long-chain hydrocarbon compounds. While it is similar to fossil fuels, it is free from sulfur and aromatics, therefore, burns soot-free.

The engineers' success can be attributed to the high temperatures used. The first step to create this eco-friendly diesel fuel is to harness renewable energy through solar, wind and/or hydropower. Then, engineers heat water to temperatures in excess of 800oC (1472oF). The steam gets broken down into oxygen and hydrogen through high-temperature electrolysis – a process where an electric current is passed through a solution, reports IFLScience. Once hydrogen is removed, it is mixed with carbon monoxide under high heat and pressure. This results in the formation of the hydrocarbon product they're calling "blue crude."

Credit: fostertire.blogspot.com