Breaking News

Ranchers in Washington are challenging the state over a fundamental constitutional question...

Ranchers in Washington are challenging the state over a fundamental constitutional question...

President Milei launched an account in English but it was suspended by X a few hours later.

President Milei launched an account in English but it was suspended by X a few hours later.

The Trump Doctrine: "They Have It. We Want It. We Take It."

The Trump Doctrine: "They Have It. We Want It. We Take It."

Event 201 Pandemic Exercise: Segment 4, Communications Discussion and Epilogue Video

Event 201 Pandemic Exercise: Segment 4, Communications Discussion and Epilogue Video

Top Tech News

Superheat Unveils the H1: A Revolutionary Bitcoin-Mining Water Heater at CES 2026

Superheat Unveils the H1: A Revolutionary Bitcoin-Mining Water Heater at CES 2026

World's most powerful hypergravity machine is 1,900X stronger than Earth

World's most powerful hypergravity machine is 1,900X stronger than Earth

New battery idea gets lots of power out of unusual sulfur chemistry

New battery idea gets lots of power out of unusual sulfur chemistry

Anti-Aging Drug Regrows Knee Cartilage in Major Breakthrough That Could End Knee Replacements

Anti-Aging Drug Regrows Knee Cartilage in Major Breakthrough That Could End Knee Replacements

Scientists say recent advances in Quantum Entanglement...

Scientists say recent advances in Quantum Entanglement...

Solid-State Batteries Are In 'Trailblazer' Mode. What's Holding Them Up?

Solid-State Batteries Are In 'Trailblazer' Mode. What's Holding Them Up?

US Farmers Began Using Chemical Fertilizer After WW2. Comfrey Is a Natural Super Fertilizer

US Farmers Began Using Chemical Fertilizer After WW2. Comfrey Is a Natural Super Fertilizer

Kawasaki's four-legged robot-horse vehicle is going into production

Kawasaki's four-legged robot-horse vehicle is going into production

The First Production All-Solid-State Battery Is Here, And It Promises 5-Minute Charging

The First Production All-Solid-State Battery Is Here, And It Promises 5-Minute Charging

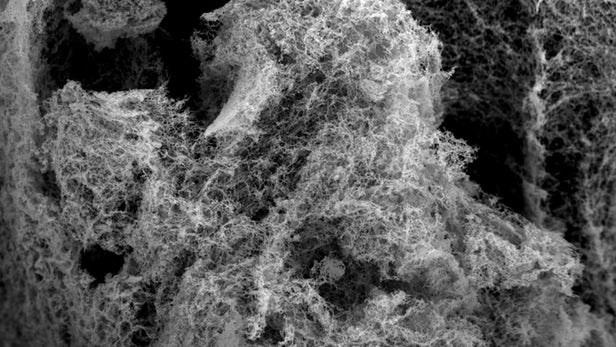

Metallic nanofoam wrings hydrogen out of water more efficiently

Zapping hydrogen out of water through a process called electrolysis is the cleanest way, but the catalysts required are rare-Earth metals like platinum. Researchers at Washington State University have now developed a quick and inexpensive alternative, making a "nanofoam" catalyst out of nickel and iron that they say performed better than usual.

Water electrolysis hasn't quite made it to industrial scale yet, mostly due to the costs of those catalysts and the high energy input required to trigger the reaction. Improving these areas is a key area of research, with scientists tackling the problem by using catalysts such as inexpensive molybdenum sulfide, and hybrid solid-state electrolyzers.

The WSU researchers used nickel and iron, two cheap and abundant metals, as a catalyst. From those they created a nanofoam, a material that resembles a sponge on the atomic level. With a large amount of surface area making contact with the water, the nanofoam is able to efficiently trigger the reaction, and the team found that the material worked better and required less energy than the more expensive catalysts, losing very little activity over a 12-hour stability test.

Storage doesn't get much cheaper than this

Storage doesn't get much cheaper than this