Breaking News

Pentagon To Send 200 Troops to Nigeria

Pentagon To Send 200 Troops to Nigeria

Trump Says He May Send Second Aircraft Carrier to Middle East To Prepare for Potential Attack...

Trump Says He May Send Second Aircraft Carrier to Middle East To Prepare for Potential Attack...

A Market Crash and Recession Are Bullish, Not Bearish

A Market Crash and Recession Are Bullish, Not Bearish

What Are They Still Hiding? New Epstein Questions Point to a Much Bigger Cover-Up

What Are They Still Hiding? New Epstein Questions Point to a Much Bigger Cover-Up

Top Tech News

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

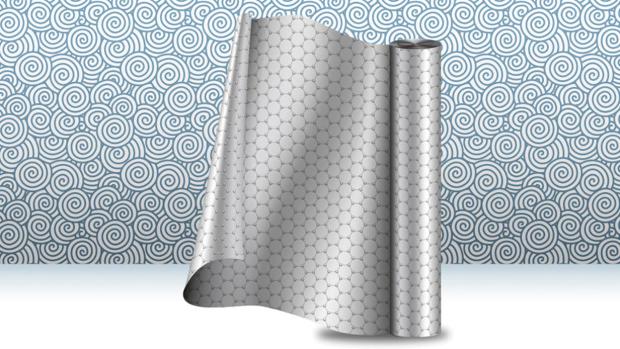

MIT researchers develop scalable manufacturing process for graphene sheets

Graphene is an ultra-light, ultra-strong, super conductive, transparent carbon allotrope that resembles a chicken wire lattice at the atomic level, one that makes it impervious to even the tiniest of atoms – helium. Thus, with the right-sized holes poked in it, it can be tailored to filter out specific molecules very effectively.

The problem has always been manufacturing the damn stuff, particularly at any kind of scale, because graphene needs to be grown under very particular conditions. And that's what an MIT team believes it's cracked, using a roll-to-roll approach that's already producing up to 10 m (33 ft) of continuous graphene at a time, at a rate of 5 cm (2 in) per minute.

The process uses chemical vapour deposition, spooling a length of copper foil between two rolls and passing it slowly through two tubes. The first tube heats the foil to an ideal temperature, and in the second, a specific ratio of methane and hydrogen gas is pumped in. When this gas mixture hits the heated foil, graphene begins to form.