Breaking News

Wednesday War Room LIVE: Fireworks As AG Pam Bondi Testifies Before Congress On Epstein Files...

Wednesday War Room LIVE: Fireworks As AG Pam Bondi Testifies Before Congress On Epstein Files...

Trans Suspect Kills Nine, Wounds 25 Before Committing Suicide In HORRIFYING Canadian...

Trans Suspect Kills Nine, Wounds 25 Before Committing Suicide In HORRIFYING Canadian...

Liberate Education from the State

Liberate Education from the State

Mark Zuckerberg buys new $150 million Miami mansion after becoming latest tech billionaire...

Mark Zuckerberg buys new $150 million Miami mansion after becoming latest tech billionaire...

Top Tech News

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

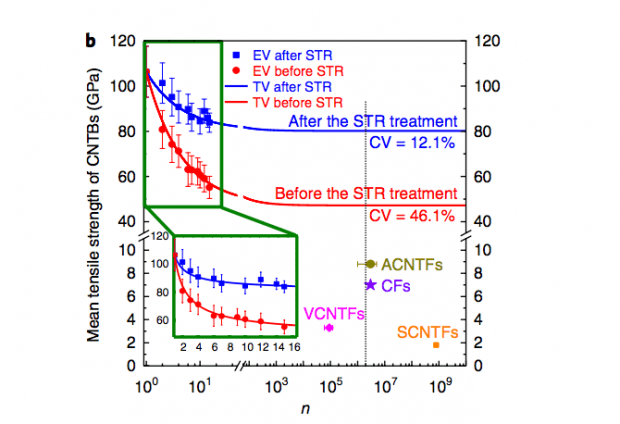

Breakthrough Carbon nanotube bundles are over 20 times stronger than Kevlar

If a more rigorous engineering definition is used, the tensile strength of macroscale CNTBs is still 5–24 times that of any other types of engineering fiber, indicating the extraordinary advantages of ultralong Carbon nanotubes in fabricating superstrong fibers.

The work was done at Tsinghua University and other facilities in Beijing. Researchers were Yunxiang Bai, Rufan Zhang, Xuan Ye, Zhenxing Zhu, Huanhuan Xie, Boyuan Shen, Dali Cai, Bofei Liu, Chenxi Zhang, Zhao Jia, Shenli Zhang, Xide Li & Fei Wei.

A synchronous tightening and relaxing (STR) strategy further improves the alignment of the carbon nanotubes to increase the strength.

Superstrong fibers are in great demand in many high-end fields such as sports equipment, ballistic armour, aeronautics, astronautics and even space elevators. In 2005, the US National Aeronautics and Space Administration (NASA) launched a 'Strong Tether Challenge', aiming to find a tether with a specific strength up to 7.5GPa cm3 per gram for the dream of making space elevators. Unfortunately, there is still no winner for this challenge. The specific strength of existing fibres such as steel wire ropes (about 0.05–0.33 GPa cm3 per gram), carbon fibres (about 0.5–3.5GPa cm3 per gram) and polymer fibers (about 0.28–4.14GPa cm3 per gram) is far lower than 7.5GPa cm3 per gram). Carbon nanotubes, with inherent tensile strength higher than 100GPa and Young's modulus over 1TPa, are considered one of the strongest known materials.