Breaking News

Satanic Ritual Abuse Survivor Exposes Epstein, the Vatican & Who Runs the World

Satanic Ritual Abuse Survivor Exposes Epstein, the Vatican & Who Runs the World

Anarchapulco 2026 begins in Puerto Vallarta, MX...

Anarchapulco 2026 begins in Puerto Vallarta, MX...

Last Chance To Avoid War With Iran?

Last Chance To Avoid War With Iran?

DOJ Says It's Done With The Epstein Files, The World Order Gets Debated In Munich

DOJ Says It's Done With The Epstein Files, The World Order Gets Debated In Munich

Top Tech News

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

AI-enhanced stethoscope excels at listening to our hearts

AI-enhanced stethoscope excels at listening to our hearts

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Display hub adds three more screens powered through single USB port

Display hub adds three more screens powered through single USB port

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

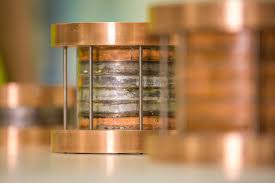

Tokamak Energy Has 24.4 Tesla High Temperature Superconducting Magnets...

The magnet is wound from REBCO (Rare earth – Barium – Copper Oxide) HTS tape. This conduction-cooled all-REBCO magnet achieved its peak field at 21K in a cold bore of 50 mm, which we believe to be record performance. In superconducting terms, 21K is a relatively high temperature. Additionally, the magnet is extremely robust, reliable and simple to manufacture. The engineers have been impressed by the defect tolerance of the coils and their response to a sudden loss of superconductivity, called a quench.

The achievement is an important milestone on the route to commercial fusion energy because high magnetic fields are necessary for tokamak machines to trap the hot fusion fuel, which is in the form of an electrically-charged gas called plasma. High temperature superconducting materials will facilitate the higher magnetic fields necessary for efficient commercial fusion reactors.

The progress of the HTS team has been faster than expected with milestones being hit well ahead of schedule (this milestone was scheduled for late 2020). The next step is to scale up these magnets into the configuration required for tokamaks.