Breaking News

Canada's Organ Harvesting just got EXPOSED, and it's Satanic | Redacted News

Canada's Organ Harvesting just got EXPOSED, and it's Satanic | Redacted News

"GRAVE CONCERNS" CRITICAL TO SUPPLYING THE NATIONS FOOD SUPPLY

"GRAVE CONCERNS" CRITICAL TO SUPPLYING THE NATIONS FOOD SUPPLY

Video Contradicts DHS Claims About Killing of Alex Pretti

Video Contradicts DHS Claims About Killing of Alex Pretti

Teslas now require a subscription for features standard in a base Kia

Teslas now require a subscription for features standard in a base Kia

Top Tech News

Researchers who discovered the master switch that prevents the human immune system...

Researchers who discovered the master switch that prevents the human immune system...

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

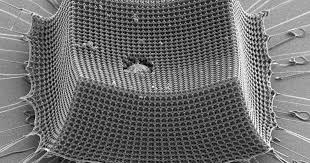

Ultralight armor material made of tiny carbon struts outperforms Kevlar

The latest example comes from material scientists at MIT, who have used advanced nanoscale engineering to craft a new armor material they say outperforms Kevlar and steel.

The starting point for the promising new material was a photosensitive resin, which was treated with lasers to form a lattice pattern made up of repeating microscopic struts. This material was then put in a high-temperature vacuum chamber, which converted the polymer into an ultralight carbon with an architecture originally inspired by special foams designed to absorb impacts.

"Historically this geometry appears in energy-mitigating foams," says lead author, Carlos Portela. "While carbon is normally brittle, the arrangement and small sizes of the struts in the nanoarchitected material gives rise to a rubbery, bending-dominated architecture."