Breaking News

Canada's Organ Harvesting just got EXPOSED, and it's Satanic | Redacted News

Canada's Organ Harvesting just got EXPOSED, and it's Satanic | Redacted News

"GRAVE CONCERNS" CRITICAL TO SUPPLYING THE NATIONS FOOD SUPPLY

"GRAVE CONCERNS" CRITICAL TO SUPPLYING THE NATIONS FOOD SUPPLY

Video Contradicts DHS Claims About Killing of Alex Pretti

Video Contradicts DHS Claims About Killing of Alex Pretti

Teslas now require a subscription for features standard in a base Kia

Teslas now require a subscription for features standard in a base Kia

Top Tech News

Researchers who discovered the master switch that prevents the human immune system...

Researchers who discovered the master switch that prevents the human immune system...

The day of the tactical laser weapon arrives

The day of the tactical laser weapon arrives

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

'ELITE': The Palantir App ICE Uses to Find Neighborhoods to Raid

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

Solar Just Took a Huge Leap Forward!- CallSun 215 Anti Shade Panel

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

XAI Grok 4.20 and OpenAI GPT 5.2 Are Solving Significant Previously Unsolved Math Proofs

Watch: World's fastest drone hits 408 mph to reclaim speed record

Watch: World's fastest drone hits 408 mph to reclaim speed record

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

Ukrainian robot soldier holds off Russian forces by itself in six-week battle

NASA announces strongest evidence yet for ancient life on Mars

NASA announces strongest evidence yet for ancient life on Mars

Caltech has successfully demonstrated wireless energy transfer...

Caltech has successfully demonstrated wireless energy transfer...

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

The TZLA Plasma Files: The Secret Health Sovereignty Tech That Uncle Trump And The CIA Tried To Bury

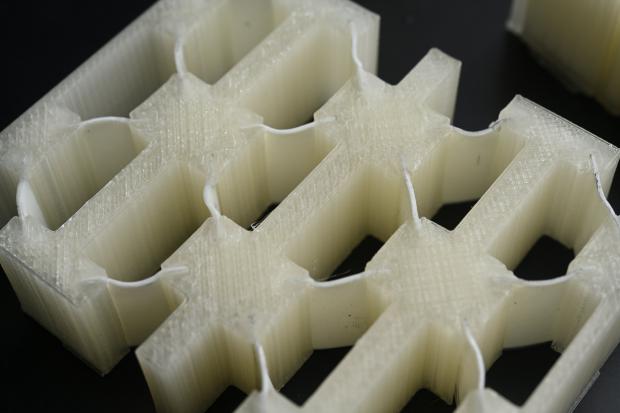

New shock-absorbing material as strong as metal but light as foam

The stuff could make for helmets, armor and vehicle parts that are lighter, stronger and, importantly, reusable.

The key to the new material is what are known as liquid crystal elastomers (LCEs). These are networks of elastic polymers in a liquid crystalline phase that give them a useful combination of elasticity and stability. LCEs are normally used to make actuators and artificial muscles for robotics, but for the new study the researchers investigated the material's ability to absorb energy.

The team created materials that consisted of tilted beams of LCE, sandwiched between stiff supporting structures. This basic unit was repeated over the material in multiple layers, so that they would buckle at different rates on impact, dissipating the energy effectively.

In a series of experiments, the team tested how well the material could withstand impacts of different masses at different speeds. The materials were struck by objects weighing between 4 and 15 lb (1.8 and 6.8 kg) at speeds of up to 22 mph (35.4 km/h) and, sure enough, they held up.

Perhaps unsurprisingly, the material performed better with more layers of the cells. A structure with four layers, for example, had almost double the energy absorption density of a single-layer structure.

While the materials were so far only tested with impacts up to 22 mph, the team says that they should be able to absorb impacts at higher speeds as well.

The researchers say that the material could be used to improve the safety of helmets, body armor, car bumpers and other parts of vehicles and aircraft, effectively dissipating energy from impacts while remaining lightweight.