Breaking News

Backed by Tech Billionaires, Silicon Valley Startup Quietly Weighs Plan...

Backed by Tech Billionaires, Silicon Valley Startup Quietly Weighs Plan...

Dentistry Lies Things Your Dentist Won't Tell You!

Dentistry Lies Things Your Dentist Won't Tell You!

Two massive quakes in 48 hours spark 'megaquake week' warnings

Two massive quakes in 48 hours spark 'megaquake week' warnings

America's Rapidly Growing Happiness Deficit

America's Rapidly Growing Happiness Deficit

Top Tech News

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

Advanced Propulsion Resources Part 1 of 2

Advanced Propulsion Resources Part 1 of 2

PulsarFusion a forward-thinking UK aerospace company, is pushing the boundaries of space travel...

PulsarFusion a forward-thinking UK aerospace company, is pushing the boundaries of space travel...

Dinky little laser box throws big-screen entertainment from inches away

Dinky little laser box throws big-screen entertainment from inches away

'World's first' sodium-ion flashlight shines bright even at -40 ºF

'World's first' sodium-ion flashlight shines bright even at -40 ºF

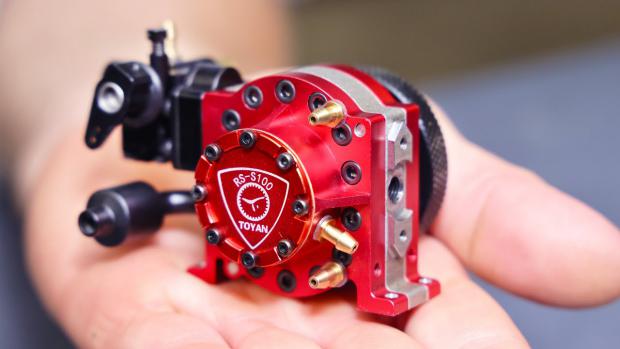

Tiny Wankel engine packs a power punch above its weight class

AIE is one of the rotary engine's biggest champions and has been advancing new rotaries via the latest manufacturing tools and techniques since 2012. Its latest release shows that Wankel engines can be a perfect fit for compact, power-demanding applications in robotics and aerospace. More palmable than a basketball, the 40ACS Wankel packs a power-to-weight punch in a package that disappears away in small spaces.

The last time we looked in on AIE (Advanced Innovative Engineering), the British company was touring and testing its 120-bhp 650S, an automotive-grade rotary engine designed to replace a traditional four-cylinder or work as an EV range-extender. That engine remains the largest unit in its lineup, and the new 40ACS drops on the opposite end of the line as one of the company's smallest offerings.

AIE has long looked to capitalize on the power-to-weight advantages of rotary design, and the aforementioned 650S boasted a 1.94 hp/lb ratio when we looked at it during development back in 2016. It packed on a little weight in production, but its power-to-weight sits at a still-solid 1.55. It puts out 2.75 lb-ft (3.73 Nm) of torque at 8,000 rpm.

Named for its 40-cc displacement, the 40ACS doesn't hit quite as high a ratio, but it still pushes comfortably past the 1.0-hp/lb mark with a 1.14 resulting from a 5-hp output and 4.4-lb (2-kg) core weight. It measures in at 6.4 in (16.3 cm) tall by 7.7 in (19.5 cm) wide by 6.7 in (17.2 cm) deep.

Additive manufacturing has been a central component of AIE's plan since launch, and the company has long relied on it in creating complex, high-performance engine structures that are also compact and lightweight. It stresses that the additive process behind the production of the 40ACS' major components was integral toward creating a small, precise engine, enhancing durability and reducing material waste.

In addition to its additive-manufactured construction, AIE keeps the 40ACS' power-to-weight in that 1+ sweet spot by applying its compact Self-Pressurizing Air-Rotor Cooling System (SPARCS). A cornerstone of the company's rotary architecture, the air-cooled SPARCS system uses gases created during combustion for cooling, eliminating parts and mass in the process.