Breaking News

Interview 1996 - The Fraud 1000x BIGGER Than Somali Day Care (NWNW #614)

Interview 1996 - The Fraud 1000x BIGGER Than Somali Day Care (NWNW #614)

1 Min Ago: MORGAN STANLEY MEMO LEAKED Exit All Silver Positions Before Month End

1 Min Ago: MORGAN STANLEY MEMO LEAKED Exit All Silver Positions Before Month End

Silver Price Collapse Begins Friday? - $14 Billion In Gold & Silver Sales Incoming

Silver Price Collapse Begins Friday? - $14 Billion In Gold & Silver Sales Incoming

Freshman Rep goes full BEAST MODE during questioning over Somali scam…

Freshman Rep goes full BEAST MODE during questioning over Somali scam…

Top Tech News

Kawasaki's four-legged robot-horse vehicle is going into production

Kawasaki's four-legged robot-horse vehicle is going into production

The First Production All-Solid-State Battery Is Here, And It Promises 5-Minute Charging

The First Production All-Solid-State Battery Is Here, And It Promises 5-Minute Charging

See inside the tech-topia cities billionaires are betting big on developing...

See inside the tech-topia cities billionaires are betting big on developing...

Storage doesn't get much cheaper than this

Storage doesn't get much cheaper than this

Laser weapons go mobile on US Army small vehicles

Laser weapons go mobile on US Army small vehicles

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

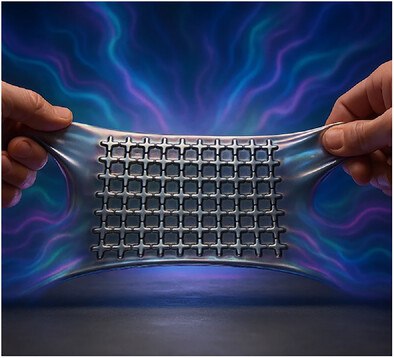

Versatile Liquid Metal Composite Inks for Printable, Durable, and Ultra-Stretchable Electronics

Abstract

Liquid metal (LM) offers exceptional potential for stretchable and flexible applications due to its outstanding stretchability, flexibility, and electrical conductivity. The inherent characteristics of LM–such as high surface tension, low viscosity, poor wettability, and sintering challenges–pose significant obstacles for use in commercial printing. To overcome these, a self-sintering liquid metal composite particle (LMCP) ink with tunable surface tension, viscosity, and wettability is developed. LMCP inks are tailored for commercial printing processes requiring low surface tension and high viscosity, enabling printing on diverse substrates. The ink achieves coffee-ring-free, crack-free, bilayer-free, and post-processing-free deposition through simple evaporation under ambient conditions, while preserving electrical conductivity. Key innovations include: i) utilizing polyvinylpyrrolidone (PVP)-capped liquid metal particles (LMPs) to reduce surface tension and enhance wettability; ii) incorporating Laponite as a viscosity enhancer and leveraging LMP sedimentation to control viscosity; iii) forming LMCPs encapsulated by PVP and Laponite through co-self-assembly on LMP surfaces to promote self-sintering; and iv) achieving uniform deposition via solutal-Marangoni-driven mixing and particle settling. The resulting LMCP electrodes exhibit over 1200% stretchability, patternability into complex configurations, and stability for nearly one year in air. Additionally, their application as stretchable metamaterial absorbers is highlighted, showcasing their potential in advanced printable electronics.

1 Introduction

In recent years, room-temperature liquid metal (LM) has been highlighted as a promising conductive material for next-generation stretchable and flexible electronics, including soft sensors and actuators,[1] wearable electronic skins,[2] stretchable displays,[3] and batteries.[4] This increasing interest is primarily due to its high electrical conductivity, even under extreme stretching conditions, and its inherent flexibility (see Table S1, Supporting Information) as well as its low toxicity compared to mercury. These unique characteristics of LMs facilitate the straightforward printing of conductive electrode patterns on a wide range of surfaces. Among various types of LM, gallium-based alloys, especially Galinstan (GaInSn), have drawn significant attention due to their ability to function effectively at sub-zero temperatures. This is due to its low melting point, while EGaIn loses its fluidic properties at near- and sub-zero temperatures; specifically, the melting temperature of Galinstan (Ga 68.5 wt%, In 21.5 wt%, and Sn 10.0 wt%) is −19.0 °C, whereas that of EGaIn (Ga 75.5 wt%, and In 24.5 wt%) is 15.5 °C.[5] However, several critical challenges arise when coating LM electrodes onto target substrates using commercial printing techniques such as inkjet, spray, stencil, roll-to-roll, and blade printing. These challenges include: i) the high surface tension of LM (greater than 0.5 N m−1 for Galinstan),[6] ii) its poor wettability on substrates, and iii) its low viscosity range (approximately 2.4 cP for Galinstan).[5]