Breaking News

If You Grew Up In The 1970s, You Probably Possess These Rare Traits

If You Grew Up In The 1970s, You Probably Possess These Rare Traits

EVEN More SUPER SHADY Financial Dealings At TPUSA!

EVEN More SUPER SHADY Financial Dealings At TPUSA!

British woman warns American about the Rise of Islam...

British woman warns American about the Rise of Islam...

Saks Global prepares for bankruptcy after missing debt payment, WSJ reports

Saks Global prepares for bankruptcy after missing debt payment, WSJ reports

Top Tech News

Laser weapons go mobile on US Army small vehicles

Laser weapons go mobile on US Army small vehicles

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

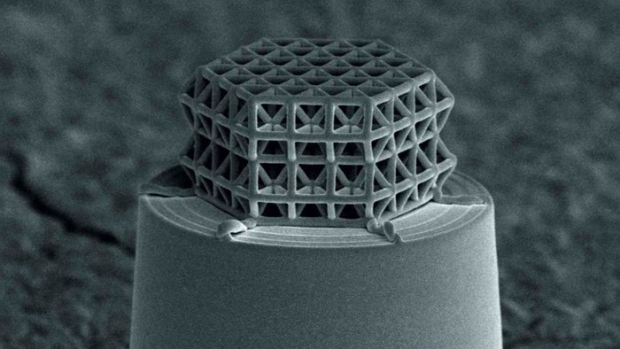

Nanoscale lattice is world's smallest

Formed with struts and braces measuring less than 10 micrometers in length and less than 200 nanometers in diameter, the 3D lattice has a total size of less than 10 micrometers, but boasts a higher specific strength than most solids.

The KIT team says the lattice achieves new strength to density ratios for metamaterials (man-made materials that have properties not found in nature), thanks to dimensions that are smaller than comparable metamaterials by a factor of five. It is made of glassy carbon, which is a form of pure carbon that boasts both glassy, ceramic properties and graphite properties.

Production of the lattice started with an established 3D lithography process, is which the structure is hardened in a photoresist by computer-controlled lasers. This process is limited to producing struts ranging from around 5 to 10 micrometers in length and 1 micrometer in diameter, so the team then vitrified and further shrunk the lattice through –in what they claim is a first for the manufacture of microstructured lattices – pyrolysis.