Breaking News

Quantum walkie-talkie: China tests world's first GPS-free radio for border zones

Quantum walkie-talkie: China tests world's first GPS-free radio for border zones

RIGHT NOW!: Why was lawyer Van Kessel, of the civil case on the merits in the Netherlands, arrested?

RIGHT NOW!: Why was lawyer Van Kessel, of the civil case on the merits in the Netherlands, arrested?

PENSION FUNDS PANIC BUYING SILVER – Ratio Below 60 Triggers $50B Wave (Danger Next Week)

PENSION FUNDS PANIC BUYING SILVER – Ratio Below 60 Triggers $50B Wave (Danger Next Week)

Dollar set for worst year since 2017, yen still in focus

Dollar set for worst year since 2017, yen still in focus

Top Tech News

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

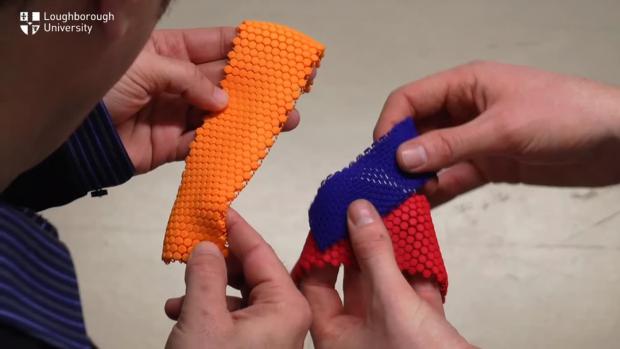

3D Fashion project set to revolutionize clothing industry

The idea is to cut out the waste of the clothing industry and hopefully arrive at the project's eventual goal, which is to provide a system for personalized, printed polymer clothing that takes just 24 hours to produce.

The clothing industry is huge, with consumers in the UK alone spending a whopping £44 billion (US$63 billion) on new garments each and every year. That consumption also generates 1.8 million tonnes (1.98 million tons) of waste material, and uses up 6.4 billion m3 of water.

Researchers at Loughborough University believe that 3D printing, also known as additive manufacturing, could truly revolutionize the industry. They note that while the practice of making clothes has been streamlined and manufacturing costs have been lowered, the underlying processes and techniques haven't really changed since the 19th century.