Breaking News

Iran (So Far Away) - Official Music Video

Iran (So Far Away) - Official Music Video

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Why America's Two-Party System Will Never Threaten the True Political Elites

Why America's Two-Party System Will Never Threaten the True Political Elites

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

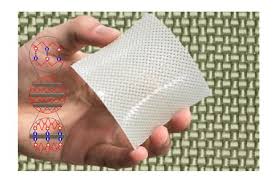

Fiber-reinforced hydrogel is 5 times stronger than steel

Hydrogels have shown significant potential in everything from wound dressings to soft robots, but their applications have been limited from their lack of toughness – until now. A team of scientists at Hokkaido University have developed a new set of hydrogel composites or "fiber-reinforced soft composites" that combine hydrogels with woven fiber fabric to create a material that is five times stronger than carbon steel.

Composite materials have been around for millennia and the principle is very simple. A very soft substance like mud can be made strong enough to make bricks by adding straw as a tempering material. The same applies to adding crushed pottery to brick, seashells fragments to ceramic, or glass fiber to plastic.

The latter is very similar to the fiber-reinforced hydrogel. Hydrogels are made of hydrophilic polymer chains that absorb up to 90 percent water. They aren't very strong or durable, but by adding glass tiny fibers the researchers created a tough, bendable, stretchable material.

Scanning Electron Microscopy (SEM) images of the fiber-reinforced hydrogels (Credit: Hokkaido University)