Breaking News

Iran (So Far Away) - Official Music Video

Iran (So Far Away) - Official Music Video

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Why America's Two-Party System Will Never Threaten the True Political Elites

Why America's Two-Party System Will Never Threaten the True Political Elites

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

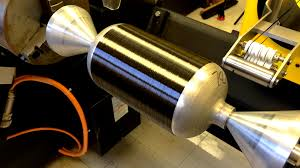

Carbon nanotube reinforce Composites can reduce space vehicle mass by 30%

NASA computer modeling analysis has shown that composites using carbon nanotube reinforcements could lead to a 30 percent reduction in the total mass of a launch vehicle.

"No single technology would have that much of an impact to reduce the mass of a launch vehicle by that much," explains Michael Meador, Program Element Manager for Lightweight Materials and Manufacturing at NASA's Glenn Research Center in Cleveland, Ohio.

Tensile properties of a carbon nanotube fiber-based composite tank were tested in a May 16 test flight.

NASA collaborated with Nanocomp in Merrimack, New Hampshire to make nanotube yarns and sheets, with the space agency developing specialized processing methods to fabricate COPVs.