Breaking News

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

COMEX Silver: 21 Days Until 429 Million Ounces of Demand Meets 103 Million Supply. (March Crisis)

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Marjorie Taylor Greene: MAGA Was "All a Lie," "Isn't Really About America or the

Why America's Two-Party System Will Never Threaten the True Political Elites

Why America's Two-Party System Will Never Threaten the True Political Elites

Generation Now #7 – Youth in Davos | Youth Pulse 2026 | Skills That Matter

Generation Now #7 – Youth in Davos | Youth Pulse 2026 | Skills That Matter

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

Stronger and tougher fiber created by MIT

Journal of Material Science – Ultrafine high performance polyethylene fibers

Abstract

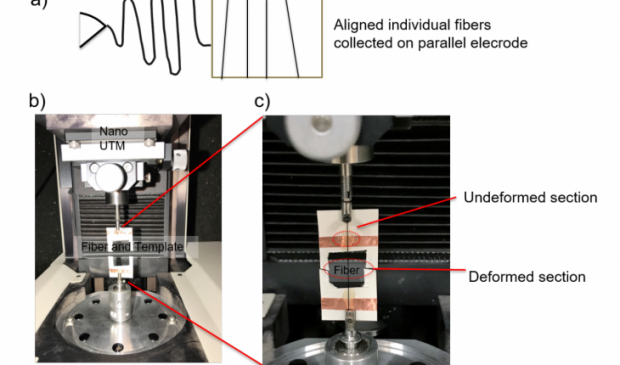

Stiff, strong and tough ultrafine polyethylene fibers that rival the best high-performance fibers, but with diameters less than one micron, are fabricated for the first time by "gel-electrospinning." In this process, solution concentration and process temperatures are chosen to induce the formation of gel filaments "in flight," which are subsequently drawn at high rates as a consequence of the whipping instability. The resulting submicron-diameter fibers exhibited Young's moduli of 73 ± 13 GPa, yield strengths of 3.5 ± 0.6 GPa, and toughnesses of 1.8 ± 0.3 GPa, on average. Among the smallest fibers examined, one with a diameter of 490 ± 50 nm showed a Young's modulus of 110 ± 16 GPa, ultimate tensile strength of 6.3 ± 0.9 GPa, and toughness of 2.1 ± 0.3 GPa, a combination of mechanical properties that is unparalleled among polymer fibers to date. The correlation of stiffness, strength and toughness with fiber diameter is attributed to high crystallinity and crystallite orientation, combined with fewer defects and enhanced chain slip associated with small diameter and high specific surface area. Gel-electrospinning improves the prospects for production of such fibers at scale.