Breaking News

2 Hours of Retro Sci-Fi Christmas Songs | Atomic-Age Christmas at a Snowy Ski Resort

2 Hours of Retro Sci-Fi Christmas Songs | Atomic-Age Christmas at a Snowy Ski Resort

Alternative Ways to Buy Farmland

Alternative Ways to Buy Farmland

LED lights are DEVASTATING our bodies, here's why | Redacted w Clayton Morris

LED lights are DEVASTATING our bodies, here's why | Redacted w Clayton Morris

Top Tech News

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

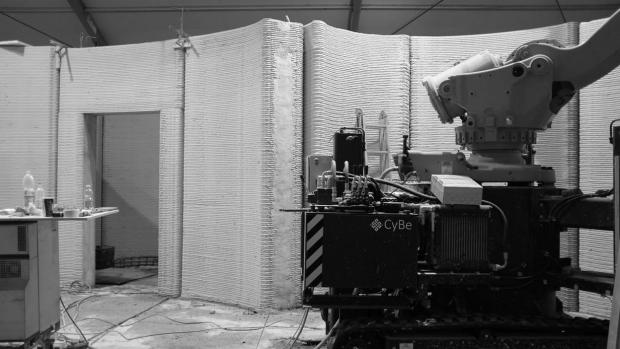

Work underway on EU's first 3D-printed concrete house

The prototype home is being constructed in Milan's central square, Piazza Cesare Beccaria, and will be officially unveiled during this year's Salone Del Mobile in April. The project also includes Italian cement supplier Italcementi and Cybe Construction.

Just like every other 3D-printed architecture project we've seen, the basic construction process involves extruding a cement mixture out of a nozzle layer by layer to build up the home's walls. However, 3D Housing 05 makes use of a robotic manipulator mounted on a movable base for increased flexibility rather than the more typical static printer.

Once the machine has done its work, humans are then required to finish off the roof, windows, and doors, as well as any other finishing touches. An Arup representative told us that the company is hoping to automate this part of the process in the future too.

$100 SILVER CONFIRMED?

$100 SILVER CONFIRMED?