Breaking News

The Self-Sufficiency Myth No One Talks About

The Self-Sufficiency Myth No One Talks About

We Investigated The Maui Fires and The Cover-Up is Worse Than We Thought | Redacted

We Investigated The Maui Fires and The Cover-Up is Worse Than We Thought | Redacted

The Amish Secret to Keeping Pests Out of Your Garden Forever

The Amish Secret to Keeping Pests Out of Your Garden Forever

Scott Ritter: Full-Scale War as Iran Attacks All U.S. Targets

Scott Ritter: Full-Scale War as Iran Attacks All U.S. Targets

Top Tech News

US particle accelerators turn nuclear waste into electricity, cut radioactive life by 99.7%

US particle accelerators turn nuclear waste into electricity, cut radioactive life by 99.7%

Blast Them: A Rutgers Scientist Uses Lasers to Kill Weeds

Blast Them: A Rutgers Scientist Uses Lasers to Kill Weeds

H100 GPUs that cost $40,000 new are now selling for around $6,000 on eBay, an 85% drop.

H100 GPUs that cost $40,000 new are now selling for around $6,000 on eBay, an 85% drop.

We finally know exactly why spider silk is stronger than steel.

We finally know exactly why spider silk is stronger than steel.

She ran out of options at 12. Then her own cells came back to save her.

She ran out of options at 12. Then her own cells came back to save her.

A cardiovascular revolution is silently unfolding in cardiac intervention labs.

A cardiovascular revolution is silently unfolding in cardiac intervention labs.

DARPA chooses two to develop insect-size robots for complex jobs like disaster relief...

DARPA chooses two to develop insect-size robots for complex jobs like disaster relief...

Multimaterial 3D printer builds fully functional electric motor from scratch in hours

Multimaterial 3D printer builds fully functional electric motor from scratch in hours

WindRunner: The largest cargo aircraft ever to be built, capable of carrying six Chinooks

WindRunner: The largest cargo aircraft ever to be built, capable of carrying six Chinooks

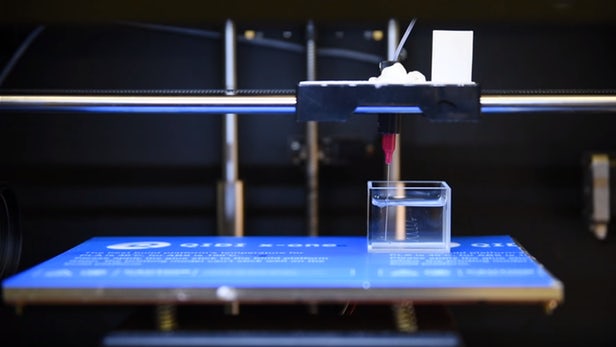

Nanoscale "supersoap" allows liquid 3D structures to be printed within other liquids

Because of a special nanoscale coating, the water structures survive without breaking down into droplets even as the encapsulating fluid changes shape. This new form of 3D printing could give rise to flexible and stretchable liquid electronics, aid chemical synthesis, or serve as a transport and delivery system for nanoscale particles.

The team of researchers led by Tom Russell modified a standard 3D printer so it would inject narrow streams of water directly into a small container filled with silicon oil. The streams of water don't break down into droplets thanks to a special nanoscale surfactant – a substance that reduces surface tension – which separates the water from the surrounding liquid.

The surfactant, a "nanoparticle supersoap," simultaneously disperses gold nanoparticles into the water and binding polymers into the oil. After water is injected, the polymers attach to individual water molecules, forming a soap, vitrifying, and locking the water structures into place even as the surrounding oil changes shape.

RNA Crop Spray: Should We Be Worried?

RNA Crop Spray: Should We Be Worried?