Breaking News

Alternative Ways to Buy Farmland

Alternative Ways to Buy Farmland

LED lights are DEVASTATING our bodies, here's why | Redacted w Clayton Morris

LED lights are DEVASTATING our bodies, here's why | Redacted w Clayton Morris

How My Youtube Channel Makes Money

How My Youtube Channel Makes Money

Top Tech News

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

A microbial cleanup for glyphosate just earned a patent. Here's why that matters

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

Japan Breaks Internet Speed Record with 5 Million Times Faster Data Transfer

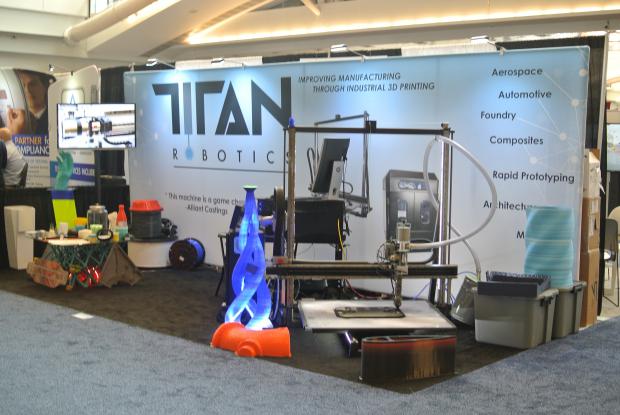

Breakthrough for large scale printing of wood at ten times lower cost than other 3D printing

The bottom-up use of cellulose to fabricate 3D objects has had big problems that prevented printing wood for practical applications. Use in combination with plastics has lacked scalability and has had high production cost.

Researchers in Singapore have demonstrated the general use of cellulose to manufacture large 3D objects. They are using fungal-like adhesive material(s) (FLAM). The cost of FLAM is in the range of commodity plastics and 10 times lower than the cost of common filaments for 3D printing, such as polylactic acid.

SUDT (Singapore University of Technology and Design) has succeeded in using the cellulose material to make a chair and a series of cellulose spheres. The team made a 1.2 meter-long turbine blade entirely out of its new material.

No Excuses: Throw A Party!

No Excuses: Throw A Party!