Breaking News

Ron's Take: The US and Iran War

Ron's Take: The US and Iran War

Kurdish Boots on the Ground with US/Israeli Air and Drones

Kurdish Boots on the Ground with US/Israeli Air and Drones

Clinton Epstein Deposition Highlights: Ex-President & Secretary Of State Grilled On Ties...

Clinton Epstein Deposition Highlights: Ex-President & Secretary Of State Grilled On Ties...

Top Tech News

US particle accelerators turn nuclear waste into electricity, cut radioactive life by 99.7%

US particle accelerators turn nuclear waste into electricity, cut radioactive life by 99.7%

Blast Them: A Rutgers Scientist Uses Lasers to Kill Weeds

Blast Them: A Rutgers Scientist Uses Lasers to Kill Weeds

H100 GPUs that cost $40,000 new are now selling for around $6,000 on eBay, an 85% drop.

H100 GPUs that cost $40,000 new are now selling for around $6,000 on eBay, an 85% drop.

We finally know exactly why spider silk is stronger than steel.

We finally know exactly why spider silk is stronger than steel.

She ran out of options at 12. Then her own cells came back to save her.

She ran out of options at 12. Then her own cells came back to save her.

A cardiovascular revolution is silently unfolding in cardiac intervention labs.

A cardiovascular revolution is silently unfolding in cardiac intervention labs.

DARPA chooses two to develop insect-size robots for complex jobs like disaster relief...

DARPA chooses two to develop insect-size robots for complex jobs like disaster relief...

Multimaterial 3D printer builds fully functional electric motor from scratch in hours

Multimaterial 3D printer builds fully functional electric motor from scratch in hours

WindRunner: The largest cargo aircraft ever to be built, capable of carrying six Chinooks

WindRunner: The largest cargo aircraft ever to be built, capable of carrying six Chinooks

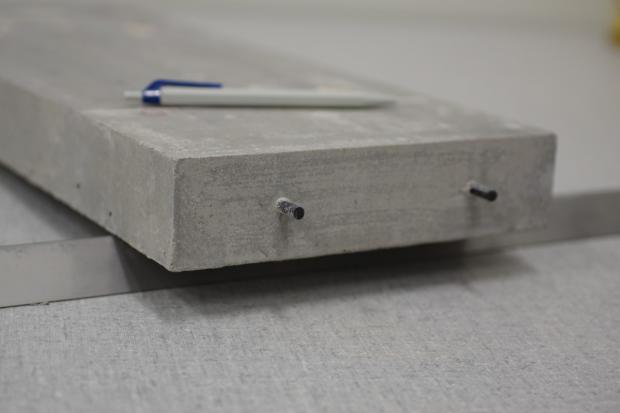

Leaner, greener, expanding concrete pre-stresses itself as it forms

A novel adaptation of this pre-stressing technique has been used to produce concrete that is lighter but with comparable strength, an advance that if widely applied, could save significant amounts of CO2.

As the most commonly used construction material in the world, the carbon footprint of concrete is massive, with the billions of tonnes produced each year requiring vast amounts of energy. For this reason, scientists all around the world are looking to tweak the production processes to make them more environmentally friendly, with even small improvements potentially having big ramifications.

The latest breakthrough comes from scientists at the Swiss Federal Laboratories for Materials Science and Technology (EMPA), where ways to improve on pre-stressed concrete technology are being investigated. This technique is often used when the material is required to withstand especially high loads, such as a beam or a bridge, with the tensioned steel tendons generating forces that compress the material from within.

Tulsi Gabbard Should Resign

Tulsi Gabbard Should Resign

RNA Crop Spray: Should We Be Worried?

RNA Crop Spray: Should We Be Worried?