Breaking News

US Lawmakers Shmooze with Zelensky at Munich Security Conference...

US Lawmakers Shmooze with Zelensky at Munich Security Conference...

Scientists have plan to save the world by chopping down boreal forest...

Scientists have plan to save the world by chopping down boreal forest...

New Coalition Aims To Ban Vaccine Mandates Across US

New Coalition Aims To Ban Vaccine Mandates Across US

Top Tech News

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

AI-enhanced stethoscope excels at listening to our hearts

AI-enhanced stethoscope excels at listening to our hearts

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Display hub adds three more screens powered through single USB port

Display hub adds three more screens powered through single USB port

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

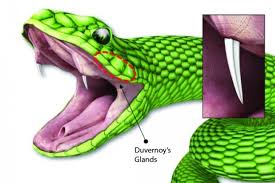

Inexpensive antivenom could reportedly be used by "anyone, anywhere

Traditionally, antivenom is produced by first "milking" venom from the fangs of captive snakes, then injecting small amounts of that venom into animals such as horses. Those creatures respond by producing venom-neutralizing antibodies which are harvested from their blood, purified, then used in the antivenom.

This can be quite a lengthy process, plus the workers who extract the venom run a risk of getting bitten by the snakes. Additionally, the antivenom must be applied intravenously, typically in a hospital or clinic

Going the Way of the Denarius

Going the Way of the Denarius