Breaking News

SEMI-NEWS/SEMI-SATIRE: February 22, 2026 Edition

The Domino Effect: How a U.S. Attack on Iran Could Unleash Global Catastrophe

The Domino Effect: How a U.S. Attack on Iran Could Unleash Global Catastrophe

Top Tech News

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

AI-enhanced stethoscope excels at listening to our hearts

AI-enhanced stethoscope excels at listening to our hearts

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Display hub adds three more screens powered through single USB port

Display hub adds three more screens powered through single USB port

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

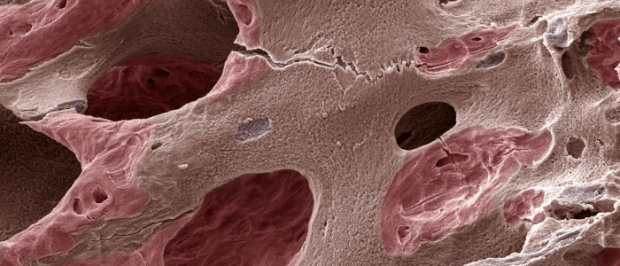

Scientists Use Novel Ink With Calcium to 3D-Print 'Bone' With Living Cells

Scientists from UNSW Sydney have developed a ceramic-based ink that may allow surgeons in the future to 3D-print bone parts complete with living cells that could be used to repair damaged bone tissue.

Using a 3D-printer that deploys a special ink made up of calcium phosphate, the scientists developed a new technique, known as ceramic omnidirectional bioprinting in cell-suspensions (COBICS), enabling them to print bone-like structures that harden in a matter of minutes when placed in water.

While the idea of 3D-printing bone-mimicking structures is not new, this is the first time such material can be created at room temperature – complete with living cells – and without harsh chemicals or radiation, says Dr Iman Roohani from UNSW's School of Chemistry.

"This is a unique technology that can produce structures that closely mimic bone tissue," he said, pointing to repairs of bone defects caused by accidents or cancer.

Associate Professor Kristopher Kilian who co-developed the breakthrough technology with Dr Roohani says the fact that living cells can be part of the 3D-printed structure, together with its portability, make it a big advance on current state-of-the-art technology.

Up until now, he says, making a piece of bone-like material to repair bone tissue of a patient involves first going into a laboratory to fabricate the structures using high-temperature furnaces and toxic chemicals.

TGIF: Immigration and Culture

TGIF: Immigration and Culture Does It Smell Like Victory?

Does It Smell Like Victory?