Breaking News

Pam Bondi says that if we prosecute everybody in the Epstein Files, the whole system will collapse

Pam Bondi says that if we prosecute everybody in the Epstein Files, the whole system will collapse

Dr Pollan at Harvard has cured schizophrenia using keto diet

Dr Pollan at Harvard has cured schizophrenia using keto diet

We are winning. Big Pharma is finding it too difficult to get new vaccines approved under Trump

We are winning. Big Pharma is finding it too difficult to get new vaccines approved under Trump

Abortion drugs discovered in Bill Gates' vaccines

Abortion drugs discovered in Bill Gates' vaccines

Top Tech News

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

Starlink smasher? China claims world's best high-powered microwave weapon

Starlink smasher? China claims world's best high-powered microwave weapon

Wood scraps turn 'useless' desert sand into concrete

Wood scraps turn 'useless' desert sand into concrete

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

Let's Do a Detailed Review of Zorin -- Is This Good for Ex-Windows Users?

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

The World's First Sodium-Ion Battery EV Is A Winter Range Monster

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

China's CATL 5C Battery Breakthrough will Make Most Combustion Engine Vehicles OBSOLETE

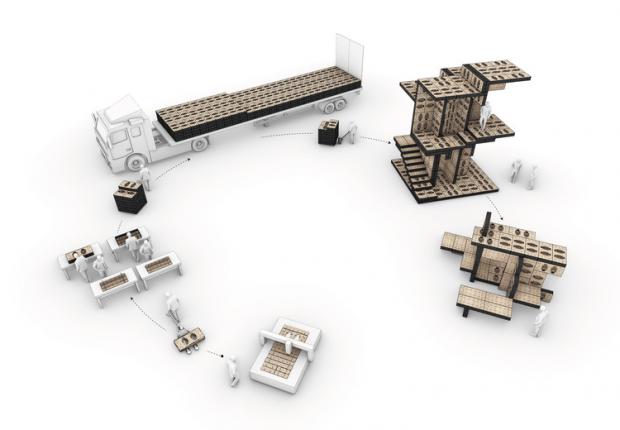

$300,000 robotic micro-factories pump out custom-designed homes

The construction industry is also the most inefficient, least digitised and most polluting industry (37% of ALL emissions), so change is imperative from macro economic necessity alone. For the builders of the world faced with a jigsaw puzzle of partial digital solutions and chronic labor and supply chain issues, the margins are growing ever-thinner and the necessity is to change or perish.

British company Automated Architecture (AUAR) has a thoroughly ingenious solution and it has enlisted an all-star cast of financial backers in short order: Morgan Stanley, ABB Robotics, Rival Holdings (USA), Vandenbussche NV (Belgium) with VCs such as Miles Ahead and Bacchus Venture Capital (Jim Horowitz et al) helping to get the initial idea off the ground.

AUAR partners with home builders and contractors in Europe and North America, licensing its micro-factory and all the digital technology to build low-energy homes at the price of normal homes, at any scale. The idea is to provide the tools to empower local ecosystems of communities, contractors, architects and developers to build better homes.

AUAR licenses the company's low CapEx robotic micro-factories and the entire tech stack required to run them, with prices starting at $300,000 plus an ongoing licensing fee. Their licensees will be existing home builders, who will be able to build homes more cost-efficiently at any scale. AUAR's customer profile is a home builder with a minimum of £20m turnover per year. There's about 3,000 of these potential customers across EU and North America.

Given robots don't need sleep or pay and work considerably faster than humans (who are in chronic short supply), AUAR's building system is expected to cut labor costs by 30% and supply chain, transport and logistics costs by 80%.

"The average home has about 7000 parts, each with a different supply chain," says AUAR's co-founder and CEO Mollie Claypool. "We have one primary material, and only a few supply chains."