Breaking News

Quantum walkie-talkie: China tests world's first GPS-free radio for border zones

Quantum walkie-talkie: China tests world's first GPS-free radio for border zones

RIGHT NOW!: Why was lawyer Van Kessel, of the civil case on the merits in the Netherlands, arrested?

RIGHT NOW!: Why was lawyer Van Kessel, of the civil case on the merits in the Netherlands, arrested?

PENSION FUNDS PANIC BUYING SILVER – Ratio Below 60 Triggers $50B Wave (Danger Next Week)

PENSION FUNDS PANIC BUYING SILVER – Ratio Below 60 Triggers $50B Wave (Danger Next Week)

Dollar set for worst year since 2017, yen still in focus

Dollar set for worst year since 2017, yen still in focus

Top Tech News

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

EngineAI T800: Born to Disrupt! #EngineAI #robotics #newtechnology #newproduct

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

This Silicon Anode Breakthrough Could Mark A Turning Point For EV Batteries [Update]

Travel gadget promises to dry and iron your clothes – totally hands-free

Travel gadget promises to dry and iron your clothes – totally hands-free

Perfect Aircrete, Kitchen Ingredients.

Perfect Aircrete, Kitchen Ingredients.

Futuristic pixel-raising display lets you feel what's onscreen

Futuristic pixel-raising display lets you feel what's onscreen

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

Cutting-Edge Facility Generates Pure Water and Hydrogen Fuel from Seawater for Mere Pennies

This tiny dev board is packed with features for ambitious makers

This tiny dev board is packed with features for ambitious makers

Scientists Discover Gel to Regrow Tooth Enamel

Scientists Discover Gel to Regrow Tooth Enamel

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Vitamin C and Dandelion Root Killing Cancer Cells -- as Former CDC Director Calls for COVID-19...

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

Galactic Brain: US firm plans space-based data centers, power grid to challenge China

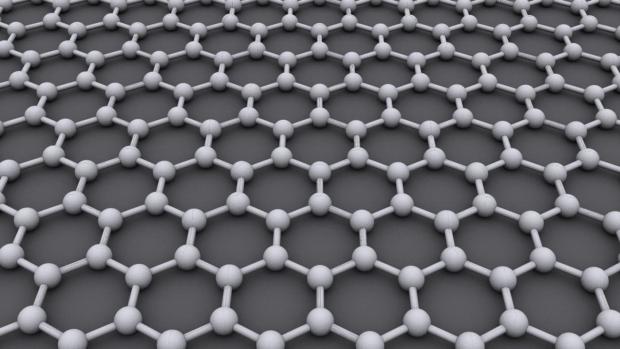

Adding silicon-sulfur into 3D graphene makes for game-changing battery potential

Chemists have long known that lithium-sulfur has huge potential as a next-generation battery solution, combining the strengths of a fuel cell (very energy dense) with the strengths of a battery (self-contained energy storage) – all in a package that is extremely environmentally-friendly and that has a low cost of manufacture.

The problem is that cathodes of sulfur and lithium have lots of material loss due to the solubility of polysulfides, and are not often efficient because sulfur has insulative properties rather than conductive. Arranging the sulfur in the lithium mix via various methods has previously shown promise, but has strict limits that have so far not allowed Li-S batteries to be viable for commercialization.

Various attempts to control the sulfur within the lithium mix have usually centered on porous carbons (usually activated carbon) for macroporous, mesoporous, and microporous solutions to make carbon-sulfur hybrids. These have worked, to a point, but have restricted pore volumes and thus limited viability. Likewise, sulfur copolymers have been a promising choice, but still have conductivity issues.