Breaking News

Battleborn Batteries Responds! Their Overheating Device is a "Feature" not a "Problem

Battleborn Batteries Responds! Their Overheating Device is a "Feature" not a "Problem

Actor Liam Neeson Outs Himself as MAHA After Narrating Pro-RFK Jr. Documentary Slamming...

Actor Liam Neeson Outs Himself as MAHA After Narrating Pro-RFK Jr. Documentary Slamming...

Kyle Rittenhouse announced on social media Wednesday that he has tied the knot.

Kyle Rittenhouse announced on social media Wednesday that he has tied the knot.

JUST IN: President Trump Grants Tina Peters Pardon

JUST IN: President Trump Grants Tina Peters Pardon

Top Tech News

Build a Greenhouse HEATER that Lasts 10-15 DAYS!

Build a Greenhouse HEATER that Lasts 10-15 DAYS!

Look at the genius idea he came up with using this tank that nobody wanted

Look at the genius idea he came up with using this tank that nobody wanted

Latest Comet 3I Atlas Anomolies Like the Impossible 600,000 Mile Long Sunward Tail

Latest Comet 3I Atlas Anomolies Like the Impossible 600,000 Mile Long Sunward Tail

Tesla Just Opened Its Biggest Supercharger Station Ever--And It's Powered By Solar And Batteries

Tesla Just Opened Its Biggest Supercharger Station Ever--And It's Powered By Solar And Batteries

Your body already knows how to regrow limbs. We just haven't figured out how to turn it on yet.

Your body already knows how to regrow limbs. We just haven't figured out how to turn it on yet.

We've wiretapped the gut-brain hotline to decode signals driving disease

We've wiretapped the gut-brain hotline to decode signals driving disease

3D-printable concrete alternative hardens in three days, not four weeks

3D-printable concrete alternative hardens in three days, not four weeks

Could satellite-beaming planes and airships make SpaceX's Starlink obsolete?

Could satellite-beaming planes and airships make SpaceX's Starlink obsolete?

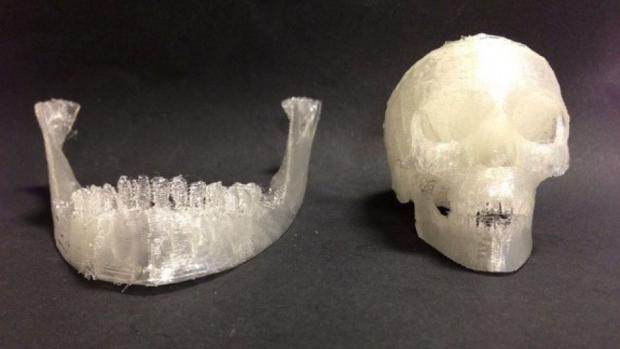

The best recipe for 3D-printed replacement bones

That's not always an ideal situation, and can lead to complications. New research coming out of the Johns Hopkins University could provide an alternative, creating custom-made, 3D-printed implants from a mixture of plastic and bone powder.

The need for replacement facial and head bones is greater than you might think, with an estimated 200,000 people requiring replacement implants as a result of surgery, trauma or birth defects. Traditionally, surgeons remove bone from the patient's leg, cutting it into the shape of the required implant.

Unsurprisingly, that option doesn't always pan out too well, with the straight nature of the leg bone making it difficult to shape effectively. Combine that with the trauma of having part a bone removed from your leg, and it's clear that a better alternative is called for.

First totally synthetic human brain model has been realized

First totally synthetic human brain model has been realized Mach-23 potato gun to shoot satellites into space

Mach-23 potato gun to shoot satellites into space