Breaking News

Why are young women attracted to older men? Men, watch and learn!

Why are young women attracted to older men? Men, watch and learn!

Voter Fraud Is About To Explode: ITS BLOWING UP IN THEIR FACES thanks to Trump and Tulsi

Voter Fraud Is About To Explode: ITS BLOWING UP IN THEIR FACES thanks to Trump and Tulsi

Ahead of US-Iran Talks, Netanyahu Tells Cabinet 'Conditions' Could Lead to Regime Change...

Ahead of US-Iran Talks, Netanyahu Tells Cabinet 'Conditions' Could Lead to Regime Change...

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

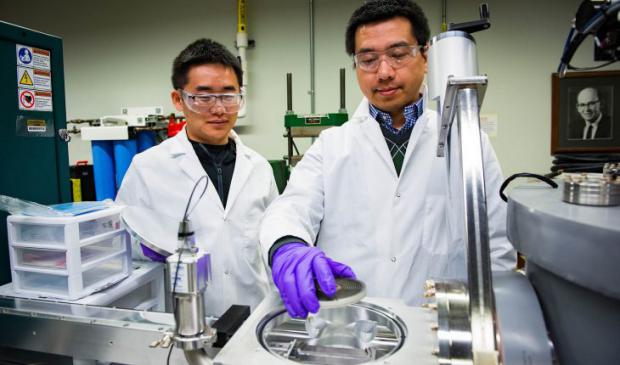

Super-strong aluminum as strong as steel

"Most lightweight aluminum alloys are soft and have inherently low mechanical strength, which hinders more widespread industrial application," said Xinghang Zhang, a professor in Purdue University's School of Materials Engineering. "However, high-strength, lightweight aluminum alloys with strength comparable to stainless steels would revolutionize the automobile and aerospace industries."

New research shows how to alter the microstructure of aluminum to impart greater strength and ductility. Findings were detailed in two new research papers. The work was led by a team of researchers that included Purdue postdoctoral research associate Sichuang Xue and doctoral student Qiang Li.

The new high-strength aluminum is made possible by introducing "stacking faults," or distortions in the crystal structure. While these are easy to produce in metals such as copper and silver, they are difficult to introduce in aluminum because of its high "stacking fault energy."