Breaking News

Why are young women attracted to older men? Men, watch and learn!

Why are young women attracted to older men? Men, watch and learn!

Voter Fraud Is About To Explode: ITS BLOWING UP IN THEIR FACES thanks to Trump and Tulsi

Voter Fraud Is About To Explode: ITS BLOWING UP IN THEIR FACES thanks to Trump and Tulsi

Ahead of US-Iran Talks, Netanyahu Tells Cabinet 'Conditions' Could Lead to Regime Change...

Ahead of US-Iran Talks, Netanyahu Tells Cabinet 'Conditions' Could Lead to Regime Change...

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Top Tech News

How underwater 3D printing could soon transform maritime construction

How underwater 3D printing could soon transform maritime construction

Smart soldering iron packs a camera to show you what you're doing

Smart soldering iron packs a camera to show you what you're doing

Look, no hands: Flying umbrella follows user through the rain

Look, no hands: Flying umbrella follows user through the rain

Critical Linux Warning: 800,000 Devices Are EXPOSED

Critical Linux Warning: 800,000 Devices Are EXPOSED

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

'Brave New World': IVF Company's Eugenics Tool Lets Couples Pick 'Best' Baby, Di

The smartphone just fired a warning shot at the camera industry.

The smartphone just fired a warning shot at the camera industry.

A revolutionary breakthrough in dental science is changing how we fight tooth decay

A revolutionary breakthrough in dental science is changing how we fight tooth decay

Docan Energy "Panda": 32kWh for $2,530!

Docan Energy "Panda": 32kWh for $2,530!

Rugged phone with multi-day battery life doubles as a 1080p projector

Rugged phone with multi-day battery life doubles as a 1080p projector

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

4 Sisters Invent Electric Tractor with Mom and Dad and it's Selling in 5 Countries

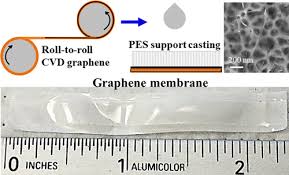

Roll-to-roll chemical vapor deposition system makes long sheets of high quality graphene

MIT has combined a roll-to-roll approach — a common industrial approach for continuous processing of thin foils — with the common graphene-fabrication technique of chemical vapor deposition, to manufacture high-quality graphene in large quantities and at a high rate.

The system consists of two spools, connected by a conveyor belt that runs through a small furnace. The first spool unfurls a long strip of copper foil, less than 1 centimeter wide. When it enters the furnace, the foil is fed through first one tube and then another, in a "split-zone" design.

While the foil rolls through the first tube, it heats up to a certain ideal temperature, at which point it is ready to roll through the second tube, where the scientists pump in a specified ratio of methane and hydrogen gas, which are deposited onto the heated foil to produce graphene.

"Graphene starts forming in little islands, and then those islands grow together to form a continuous sheet," Hart says. "By the time it's out of the oven, the graphene should be fully covering the foil in one layer, kind of like a continuous bed of pizza."

The researchers found that they were able to feed the foil continuously through the system, producing high-quality graphene at a rate of 5 centimeters per minute. Their longest run lasted almost four hours, during which they produced about 10 meters of continuous graphene.