Breaking News

Satanic Ritual Abuse Survivor Exposes Epstein, the Vatican & Who Runs the World

Satanic Ritual Abuse Survivor Exposes Epstein, the Vatican & Who Runs the World

Anarchapulco 2026 begins in Puerto Vallarta, MX...

Anarchapulco 2026 begins in Puerto Vallarta, MX...

Last Chance To Avoid War With Iran?

Last Chance To Avoid War With Iran?

DOJ Says It's Done With The Epstein Files, The World Order Gets Debated In Munich

DOJ Says It's Done With The Epstein Files, The World Order Gets Debated In Munich

Top Tech News

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

AI-enhanced stethoscope excels at listening to our hearts

AI-enhanced stethoscope excels at listening to our hearts

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Display hub adds three more screens powered through single USB port

Display hub adds three more screens powered through single USB port

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

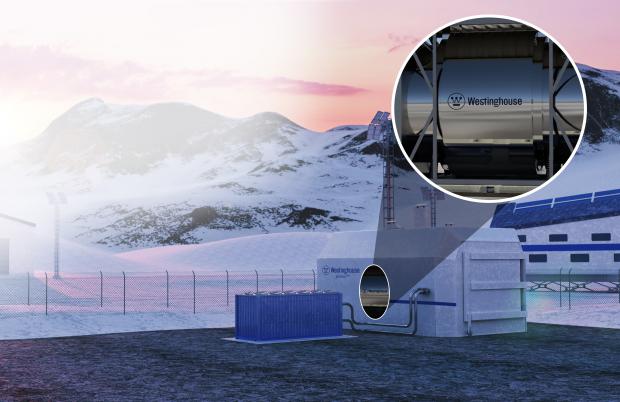

Clean energy breakthrough: eVinci nuclear microreactor from Westinghouse...

The Department of Energy has awarded the eVinci Microreactor by Westinghouse a prestigious Front-End Engineering and Experiment Design (FEEED) contract, which will help to deploy the company's nuclear test reactor at Idaho National Lab (INL).

The nuclear microreactor marks a significant energy breakthrough, providing safe, carbon-free energy that is easily scalable and highly portable. It can be used to provide heating and electricity to everything from data centers and defense facilities to mining operations, remote communities and eventually the surface of the moon.

What sets it apart from other solutions is its low number of moving parts, which enables it to act like a battery while providing up to 5 megawatts of electricity around the clock for more than eight years without the need to refuel. It does not need water for operation or cooling, and spent fuel can be sent to the manufacturer for long-term storage. It is also capable of providing high-temperature heat for a range of industrial applications, such as the production of alternative fuels like hydrogen fuel.

Another benefit of this novel microreactor is that it is fully factory assembled and can be sent to the site where it is to be used in a shipping container via truck, barge or rail. It is installed above the ground and requires minimal onsite personnel to operate, secure and maintain.

The microreactor is driven by Westinghouse's advanced heat pipe technology, which boasts superior reliability and eliminates a host of risks, from those related to coolant loss and high system pressures to the vibration and flow-induced corrosion that forced flow systems are vulnerable to.