Breaking News

"The World Is in Peril": AI Researcher Resigns and Issues Warning for Humanity

"The World Is in Peril": AI Researcher Resigns and Issues Warning for Humanity

President Obama declares aliens are REAL as he gives inside track on Area 51

President Obama declares aliens are REAL as he gives inside track on Area 51

Epstein survivor breaks down in tears as she recounts thinking she was 'going to die'...

Epstein survivor breaks down in tears as she recounts thinking she was 'going to die'...

Biggest Correction Ever? Silver's Violent Smashdown, and Why the Bull Survives

Biggest Correction Ever? Silver's Violent Smashdown, and Why the Bull Survives

Top Tech News

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

New Spray-on Powder Instantly Seals Life-Threatening Wounds in Battle or During Disasters

AI-enhanced stethoscope excels at listening to our hearts

AI-enhanced stethoscope excels at listening to our hearts

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Flame-treated sunscreen keeps the zinc but cuts the smeary white look

Display hub adds three more screens powered through single USB port

Display hub adds three more screens powered through single USB port

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

We Finally Know How Fast The Tesla Semi Will Charge: Very, Very Fast

Drone-launching underwater drone hitches a ride on ship and sub hulls

Drone-launching underwater drone hitches a ride on ship and sub hulls

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

Humanoid Robots Get "Brains" As Dual-Use Fears Mount

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

SpaceX Authorized to Increase High Speed Internet Download Speeds 5X Through 2026

Space AI is the Key to the Technological Singularity

Space AI is the Key to the Technological Singularity

Velocitor X-1 eVTOL could be beating the traffic in just a year

Velocitor X-1 eVTOL could be beating the traffic in just a year

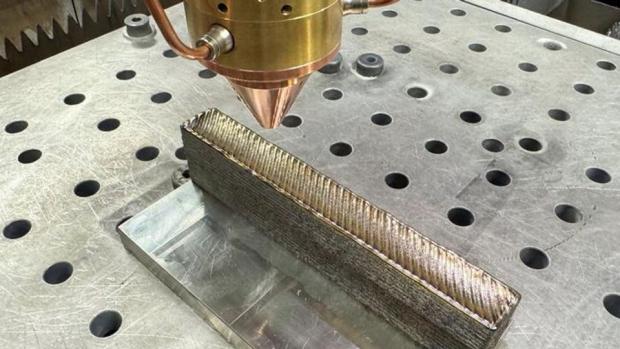

New 3D-printed titanium alloy is stronger and cheaper than ever before

Because they have exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility, titanium alloys are used to make aircraft frames, jet engine parts, hip and knee replacements, dental implants, ship hulls, and golf clubs.

Ryan Brooke, an additive manufacturing researcher at Australia's RMIT University, believes we can do way better. "3D printing allows faster, less wasteful and more tailorable production yet we're still relying on legacy alloys like Ti-6Al-4V that doesn't allow full capitalization of this potential," he says. "It's like we've created an airplane and are still just driving it around the streets."

Ti-6Al-4V is also known as Titanium alloy 6-4 or grade 5 titanium, and is a combination of aluminum and vanadium. It's strong, rigid, and highly fatigue resistant. However, 3D-printed Ti-6Al-4V has a propensity for columnar grains, which means that parts made from this material can be strong in one direction but weak or inconsistent in others – and therefore may need alloying with other elements to correct this.

To be fair, Brooke is putting his money where his mouth is. He's authored a paper that appeared in Nature this month on a new approach to finding a reliable way to predict the grain structure of metals made using additive manufacturing, and thereby guide the design of new high-performance alloys we can 3D print.

The researchers' approach, which has been in the works for the last three years, evaluated three key parameters in predicting the grain structure of alloys to determine whether an additive manufacturing recipe would yield a good alloy:

Non-equilibrium solidification range(ΔTs): the temperature range over which the metal solidifies under non-equilibrium conditions.

Growth restriction factor (Q): the initial rate at which constitutional supercooling develops at the very beginning of solidification.

Constitutional supercooling parameter (P): the overall potential for new grains to nucleate and grow throughout the solidification process, rather than just at the very beginning.

Through this work, the team experimentally verified that P is the most reliable parameter for guiding the selection of alloying elements in 3D-printed alloys to achieve desired grain structures for strength and durability.